Hinged joints

Every series of transport containers has its own tailor-made peculiarities. For this reason, Woeste has developed several models of hinged joints to deal with the many different requirements.

Hinged joint with a bolt for individual locking (fixed swivelling axis)

The post is unlocked by raising the bolt. Cross-linked posts are unlocked successively: the first raised bolt is placed in the U-profile where it is held while the next bolt is raised. This enables the hingeing function. When the posts are moved to the upright position, they are automatically locked again as the bolts slide back into their original positions.

Hinged joint with inclined sliding surfaces

In this hinged joint, the latch works in conjunction with additional inclined sliding surfaces. The effect of the inclined surfaces is enhanced by the stacked load acting on them. The force exerted vertically downwards by the load forces the folding section into a defined position that releases load from the locking mechanism. Where there is no stacked load, the joint can easily be folded over the inclined sliding surfaces after it is unlatched.

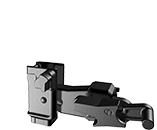

Hinged joint with a lift-out function

Lifting the post releases the internal hinge locking mechanism and enables the folding function. To lock the post again, the folded down post is simply returned to its upright position without any further effort.

Special hinged joint with a lift-out function

This special design enables long posts located directly opposite each other to fold down over each other and parallel to each other. This keeps the folded-down height as low as possible. Due to the special functionality of this construction, the joint is only suitable for lighter transport applications and must always be fitted with a crossbar between two posts that fold down the same way.